It’s no secret that software selection and reliability are critical to the return on investment (ROI) for energy storage projects. An energy storage system’s (ESS) performance depends on the quality of the system’s modeling, forecasting, and control capabilities, meaning that your software’s specifications can determine the success (or lack thereof) of your projects.

Project developers, financiers, and host customers need proven prediction, control, and monitoring capabilities to monetize energy storage investments successfully. This especially applies to high-stakes scenarios, being the case for monthly demand charge management or application stacking. With the highest quality of software selection and quality data input, monetizing energy storage assets and eliminating performance risks is made possible.

Advanced vs. Simple Controls Software

In solar-only applications, the software is oftentimes an onlooker, whereas it is the opposite when it comes to an ESS. It is impossible to generate returns on an ESS without controls software, which is why customers require sophisticated and advanced monitoring, prediction, and control components for their investment.

There are many inverter and battery vendors in the market that offer a simple software solution to provide an asset with operating and monitoring capabilities. However, oftentimes systems require a higher-level energy management system (EMS) to dispatch an asset to achieve optimal economic performance, maximize savings, and validate and improve real-world performance over time. Advanced software controls are vital for complex energy storage use cases and scenarios where multiple value streams are captured concurrently.

Artificial Intelligent (AI) provides time-series forecasts to enable operational algorithms to make optimal decisions for EMS. AI and machine learning also have applications in an EMS. The forecasts predict the site power demand and on-site renewable energy generation, with the difference between these values, ultimately determining the site’s forecasted net power demand. Machine learning models enable control software to find patterns according to time, weather, and a variety of other factors.

The Layers of Software for an ESS

When dispatching an ESS and achieving maximum value, there are three essential software layers. First and foremost is the battery management system (BMS), an input/output (I/O) interface that functions as the battery’s operating system. The BMS is not equivalent to the EMS as it cannot tell the integrated system what to do and when.

The second software layer is the EMS, which is the system operator and integrates an I/O interface for the battery, inverter, and any other hardware required for the system. The system is fully controlled by this software layer, so the higher level of sophistication the EMS can offer, which will work in conjunction with the BMS, the higher the value creation in the ESS applications. These advanced controls can also help demonstrate the competitiveness of a storage project.

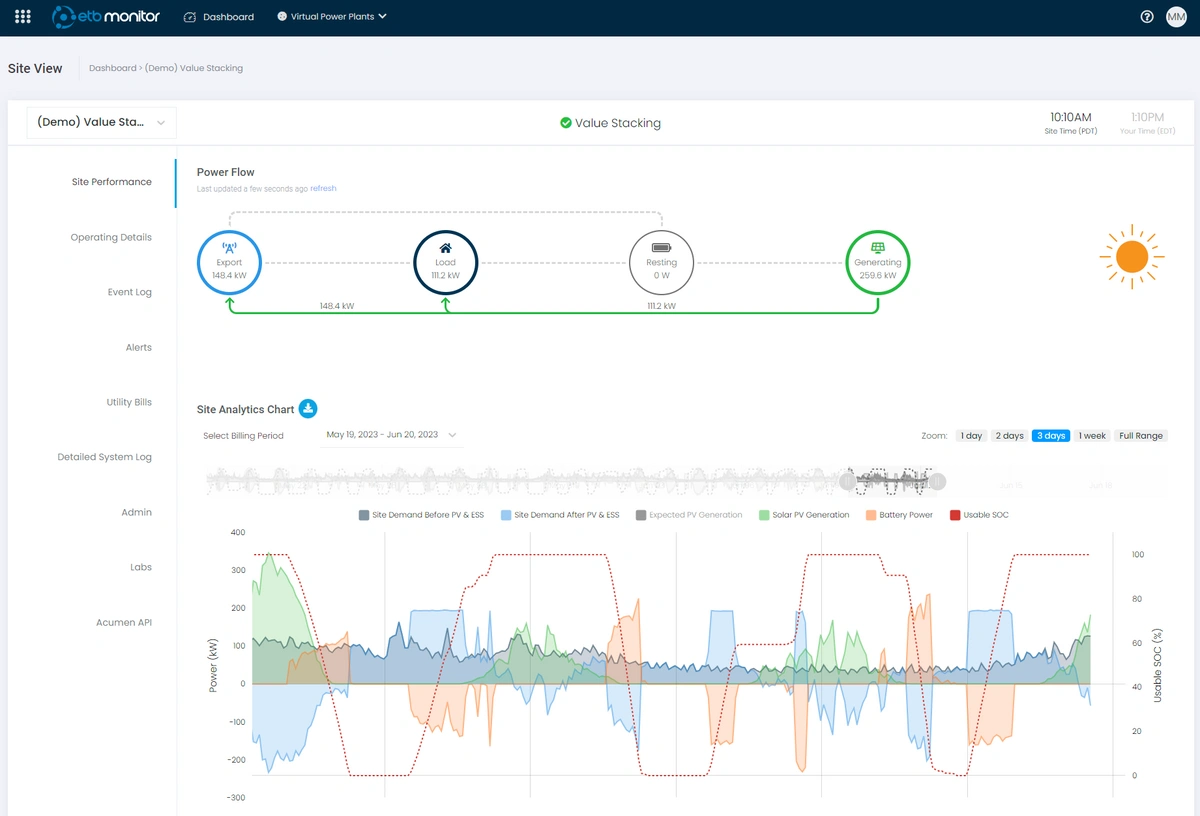

The third software layer of an ESS is the monitoring system, offering insights in real-time into the performance and savings of the ESS. System monitoring is essential in energy storage applications, and some companies do not offer a monitoring platform that allows you to transparently evaluate the advanced control capabilities required to monetize a battery. In other words, simple storage-monitoring platforms do not necessarily provide advanced control capabilities.

Maximizing Value with Software – ETB Developer, Acumen EMS™, and ETB Monitor

Energy Toolbase’s industry-leadingETB Developer modeling platform perfectly fits systems for optimal returns and estimates ESS performance according to the customer’s rate structure and load profile.Acumen EMS™ employs advanced AI and machine learning models to predict each site’s optimal charge and discharge schedules. As an EMS software provider, Energy Toolbase resolves problems hands-on by coordinating with hardware vendors, project developers, and host customers. Our operations team leads in the commissioning of projects, monitors assets, and troubleshoots issues. Our fleet-level monitoring data shows that Acumen EMS software averages more than 99% uptime in production deployments where hosts meet internet connectivity requirements. This is attributed to not only the fact that Acumen runs locally on a ruggedized industrial computer but also our operations team’s excellent ability to pinpoint and rapidly pinpoint errors in fielded assets.

Energy Toolbase’s Acumen EMS provides advanced system control capabilities whileETB Monitor effectively serves as the user interface (UI) layer, providing robust monitoring capabilities. Project developers and host customers with Acumen EMS– controlled assets can use ETB Monitor to view real-time system performance. This UI also provides a detailed breakdown of the precise utility bill savings associated with both energy storage and solar.

Image 1: ETB Monitor dashboard showing a view of the Power Flow and Site Analytics Charts for an entire fleet via the Vritaul Power Plans feature

Acumen is currently deployed and contracted on 100+ sites across North, South, and Central America. Set up a call with our team to learn more about how Acumen EMS for your storage projects or would like to have an energy storage consultation.