It’s important that solar + storage developers have a general understanding of the physical components that make up an Energy Storage System (ESS). When dealing with potential end customers, it gives credibility to have a technical understanding of the primary function of different components and how they interoperate to ensure maximum savings and performance. At Energy Toolbase, our team fields numerous questions on this topic, so we decided to summarize our answers into a blog.

For this blog, we focus entirely on lithium-ion (Li-ion) based batteries, the most widely deployed type of batteries used in stationary energy storage applications today. The International Energy Agency (IEA)reported that lithium-ion batteries accounted for more than 90% of the global investment in battery energy storage in 2020 and 2021.

Battery

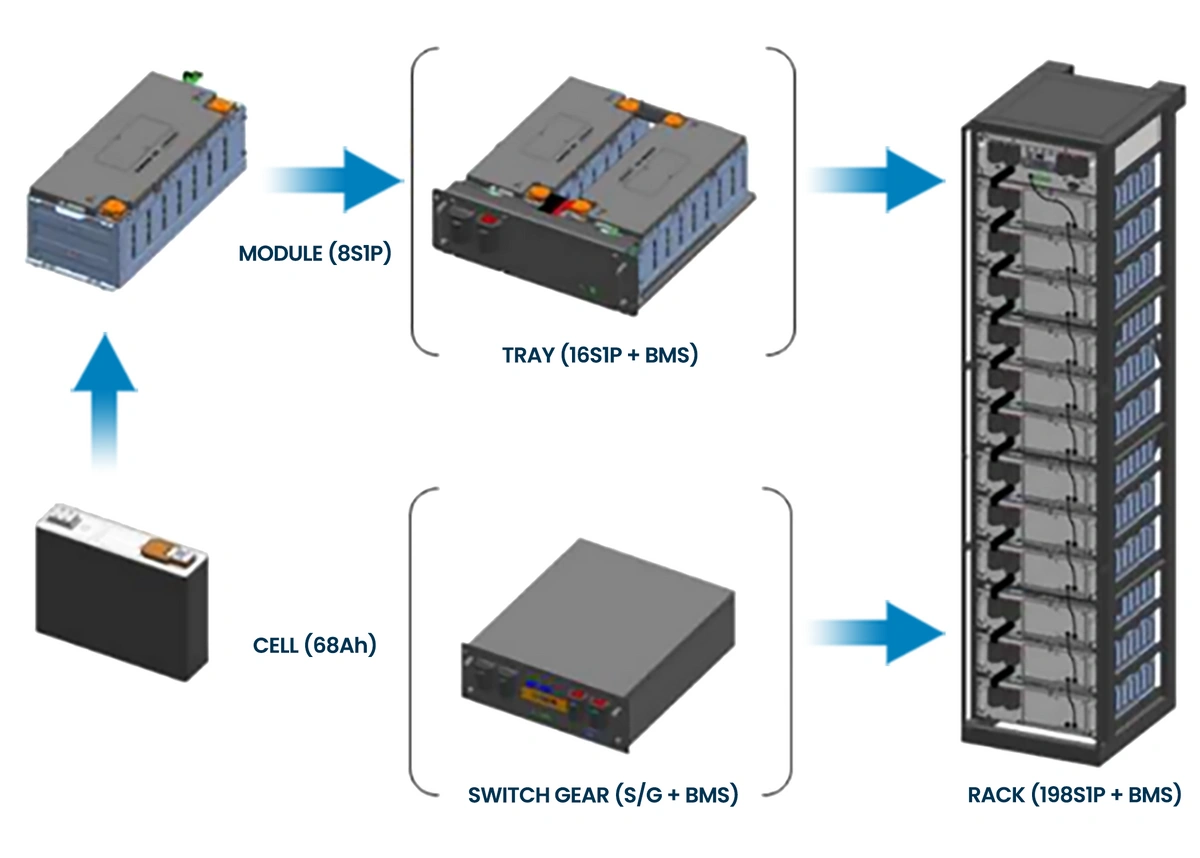

The battery is the basic building block of an electrical energy storage system. The composition of the battery can be broken into different units as illustrated below.

At the most basic level, an individual battery cell is an electrochemical device that converts stored chemical energy into electrical energy. Each cell contains a cathode, or positive terminal, and an anode, or negative terminal. An electrolyte promotes ions to move between the electrodes and terminals, allowing current to flow out of the battery to perform work. A cell is effectively the smallest, packaged form a battery can take. These battery cells are combined in a frame to form a module. This is generally done by assembling a fixed number of cells connected in a series or parallel. A cluster of battery modules is then combined to form a tray, which, as illustrated in the graphic above, may get packaged with its own Battery Management System (BMS). For specific makes and models of energy storage systems, trays are often stacked together to form a battery rack.

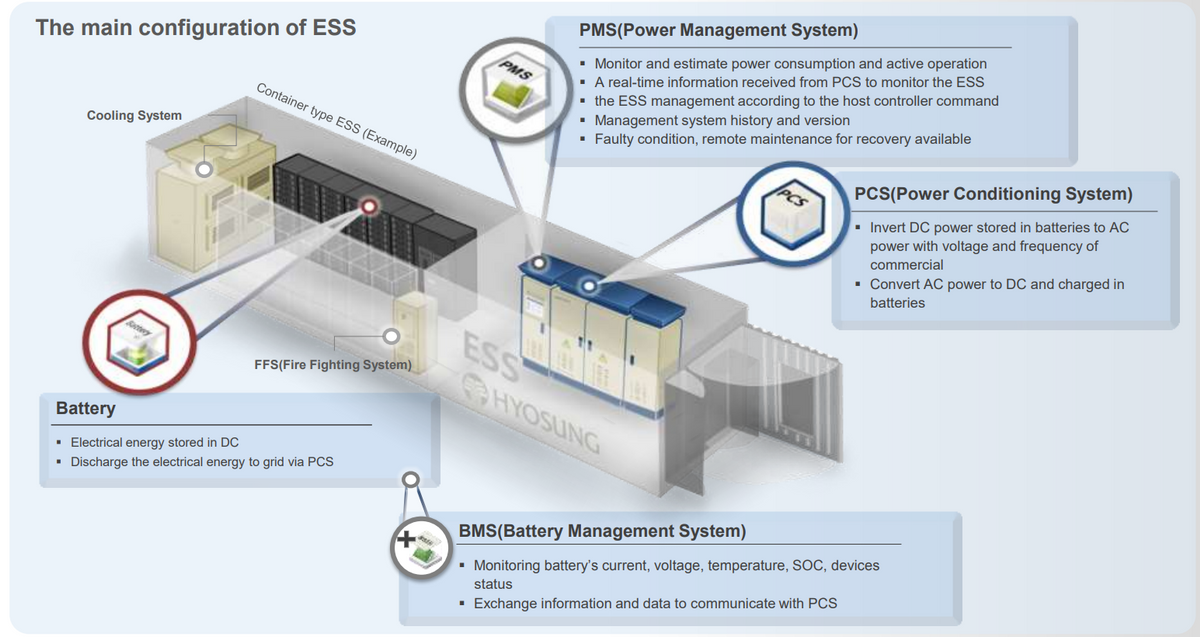

Battery Management System (BMS)

The Battery Management System (BMS) is a core component of any Li-ion-based ESS and performs several critical functions. The BMS does not provide the same functionalities as an Energy Management System (EMS). The primary job of the BMS is to protect the battery from damage in a wide range of operating conditions. It does so by ensuring that the battery cells operate within their prescribed operating windows for the state of charge, voltage, current, and temperature. This is especially important for high-power density Li-ion batteries to prevent fires or explosions caused by thermal runaway and combustion. Generally, each manufacturer explicitly designs this software and is insular to the site. A BMS typically does not natively communicate with external devices nor use a standardized protocol

The BMS is constantly monitoring critical information of the battery bank from individual cells, battery modules, and racks. This includes recording vital electrical operating parameters as well as electrolyte levels, internal cell temperature, and ambient battery enclosure temperature. It may also be coordinating any necessary mechanical HVAC measures. All this information is collected and used for proper maintenance and runtime estimates of the battery asset. The BMS also ensures that the battery cells remain balanced at the same state of charge. Any imbalance across the battery bank terminals can cause cells to get stressed and reduce the overall cycle life of the battery.

Power Conversion System (PCS) or Hybrid Inverter

Like a solar PV system, a Li-ion battery bank requires an inverter to produce an alternating current (AC) that is usable in buildings. Also referred to as Power Conditioning Systems or battery hybrid inverters, these devices are more dynamic than a typical PV inverter because they can operate bi-directionally. This means power can flow from DC to AC or vice-versa, enabling the ESS to charge and discharge. The PCS directs the energy flow by commanding the battery’s charge and discharge behavior. To do so, the hybrid inverter needs to be well informed on the available capacity of the battery so it knows to stop charging when it is full. In this fashion, the Power Conditioning System is responsible for the low-level electrical functions on site. These reactions can be driven by on-site metered information or external signals about when to charge and discharge the system for maximum effect.

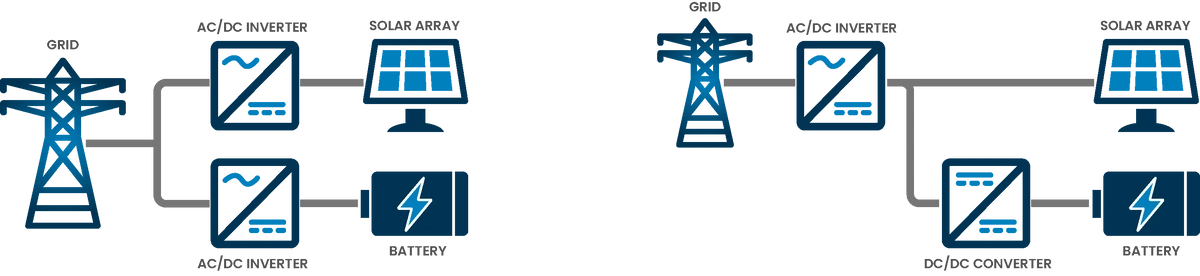

In the context of a PCS, it is essential to distinguish between AC-coupled vs DC-coupled systems. For a solar + storage system, there is a choice between connecting the battery directly on the same DC bus where the PV lands (DC coupling) or connecting the external of the PV system on the AC side of the PV inverter (AC coupling). Therefore, AC vs. DC coupling refers to how the battery is interconnected to the rest of the system. A DC-coupled system has only one inverter shared between the PV and battery. In contrast, an AC-coupled system has its dedicated inverter strictly connected to the battery. An AC-coupled system can only draw from AC energy to charge. A DC-coupled system can charge directly from the DC-coupled PV or via AC energy on the opposite side of the hybrid inverter. Each architecture has pros and cons, which we will discuss in a separate article. When making this design decision, storage developers must consider various factors, including electrical constraints, system efficiency, interconnection limitations, monitoring requirements, policies and regulations, and site access.

Energy Management System (EMS)

The energy management system handles the controls and coordination of ESS dispatch activity. The EMS communicates directly with the PCS and BMS to coordinate on-site components, often by referencing external data points. The EMS is responsible for deciding when and how to dispatch, generally driven by an economic value stream, such as demand-charge management, time-of-use arbitrage, or solar self-consumption. EMS software attempts to optimize the performance of the ESS by weighing long-term cycling and capacity degradation with the asset’s return on investment. This involves knowing the BMS and PCS limitations and recognizing when the energy storage system can be used most effectively.

The programmed behavior and sophistication of the EMS deployed can vary based on the application. Specific sites, customers, and regulatory environments only require a simple coordinated discharge during a pre-specific Time-of-use (TOU) window. In other cases, the EMS may need to employ advanced machine learning algorithms to co-optimize multiple value streams concurrently, both behind and in front of the meter. Acumen EMS™ controls software uses advanced AI and machine learning models to predict each site’s optimal charge and discharge schedules.

The operational mode of the EMS for a specific site is generally determined in advance by simulating the control strategies for the project. The EMS is responsible for making proper decisions to maximize required outcomes from the asset while simultaneously balancing those decisions with long-term asset management of the system. Acumen EMS combines behind-the-meter and front-of-the-meter strategies to generate the highest revenues from your asset, including demand charge management, time-of-use arbitrage, PV self-consumption, demand response programs, and wholesale market participation.

The EMS also serves as a single collection point for the performance data of an ESS. The EMS is optimally situated to gather, transmit, and analyze ESS information from the site. This places the EMS and its users in the best position to maintain the asset and address any issues on site. A proper EMS will be accompanied by a robust data collection and presentation platform, which enables end-users and responsible parties to access information regularly for system reporting and diagnostic exercises.

Control & Monitor your Energy Storage Assets with Acumen EMS

Energy Toolbase’sAcumen EMS provides advanced system control capabilities, whileETB Monitor effectively serves as the user interface (UI) layer, providing robust monitoring capabilities. Project developers and host customers with Acumen EMS– controlled assets can useETB Monitor to view real-time system performance and diagnose and resolve issues. This UI also provides a detailed breakdown of the utility bill savings associated with energy storage and solar.

Acumen is deployed and contracted on100+ sites across North, South, and Central America. With years of experience operating storage assets in the field and training machine learning models, our team brings skillsets in data science, utility rates, project development, and system commissioning and operation. We continuously monitor rate tariff changes and DR programs and re-optimize our dispatch algorithms to maximize value capture.

Energy Toolbase provides developers that install energy storage paired with Acumen EMS with project-level support services, including hardware procurement, commissioning support, microgrid engineering, ongoing monitoring, incentive administration, and more.Connect with our team today to talk about your energy storage projects.