Every energy storage system (ESS) is different, and every site requires a different control strategy. Specific control software is needed on an ESS, one of which is a fixed or dynamic scheduler, and these options provide substantially different results in project savings.

Energy Toolbase’sAcumen EMS™ dynamic control software makes a compelling case for any energy storage system, offering more benefits than its fixed control counterparts. We ran simulations on various thresholds for fixed controls and compared them with dynamic controls to demonstrate the difference in value capture between these strategies.

Fixed Threshold Shaving

Fixed threshold shaving uses a fixed threshold to determine whether to charge or discharge, charging the battery while the site load is below the fixed threshold and discharging while the site load is above the fixed threshold. This can be expanded if the controller has the functionality to “block” specific time windows to optimize around high-cost energy windows.

This strategy is most advantageous when the site load is extremely consistent from billing period to billing period, with little to no seasonality in the load. A fixed schedule strategy is also most advantageous when the customer has a simple dispatch they are looking to achieve (i.e., charge during specific hours, discharge during specific hours), or when the customer has a large battery capable of compensating for variations in the load sizes that need to be shaved. This strategy is also cheaper to implement as it doesn’t require forecasting or more engineering work to function, it’s simply a user input.

However, a fixed schedule is not the best option in certain circumstances. For example, with most profiles, if the site load varies by season or if time-of-use windows differ depending on billing periods or seasons (mainly in California), fixed threshold controls would not be the optimal choice. Additionally, you would not want to use fixed controls if the EMS is not equipped to handle more than one TOU window, as manually updating the TOU windows is an unreasonable task that is not efficient. Fixed threshold shaving should not be used when there are constant updates to policies and rate schedules or when the economics of a renewable project are likely to change.

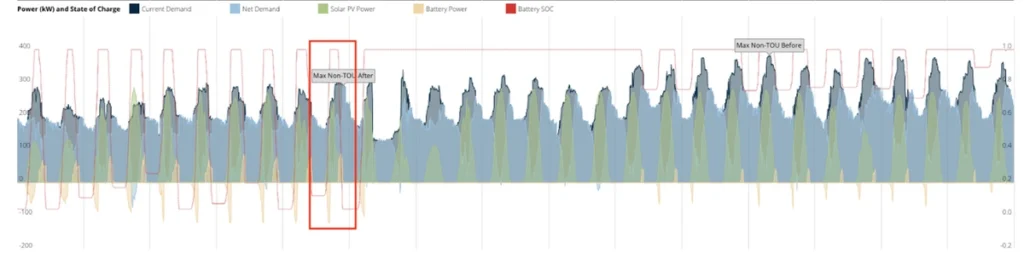

Figure 1: A fixed threshold shaver with the threshold set too low.

In Figure 1 (above), the fixed threshold is set too low. The ESS cannot maintain the low threshold, and the peak is set early in the month. The ESS continues to cycle unnecessarily to avoid demand in future days. However, this degrades the battery unnecessarily, and the charging costs become increasingly expensive.

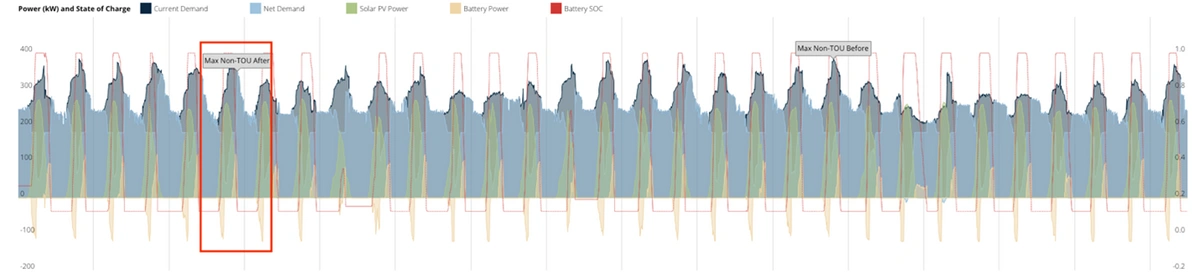

Figure 2: A fixed threshold shaver with the threshold set too high.

In Figure 2, the fixed threshold is set too high, and the battery isn’t used at all during the month. The investment in the ESS is not recouped at all during this period.

Dynamic Threshold Shaving with Pricing Intelligence

In dynamic threshold shaving, an EMS, such as Acumen, chooses its threshold for demand charge management using sophisticated methods across several TOU windows based on historical and forecasted load and PV data.

Without a doubt, properly implementing controls that are equipped to handle the wide variety of rates, tariff structures, and incentive programs, combined with varying load patterns nearly every commercial site has, is more complicated and costly to develop. However, a more sophisticated EMS is oftentimes needed. Things to consider that may help lead a customer down the sophisticated EMS route would be, whether is your EMS configured properly for your load pattern, how will you validate your savings post-deployment, who is responsible for maintaining the system through its lifecycle, and does the EMS adjust when new peaks are set?

Dynamic threshold shaving is a good solution in specific scenarios, such as when site load varies according to season (as in most site load profiles), when multiple time-of-use (TOU) windows vary based on billing periods or seasons, or when rate schedules and policies frequently change, causing pricing information to go out of date quickly. This strategy is also suitable when the battery is sized according to the best economic return it can achieve based on bill savings, as well as when battery degradation occurs, leading to less energy available over time.

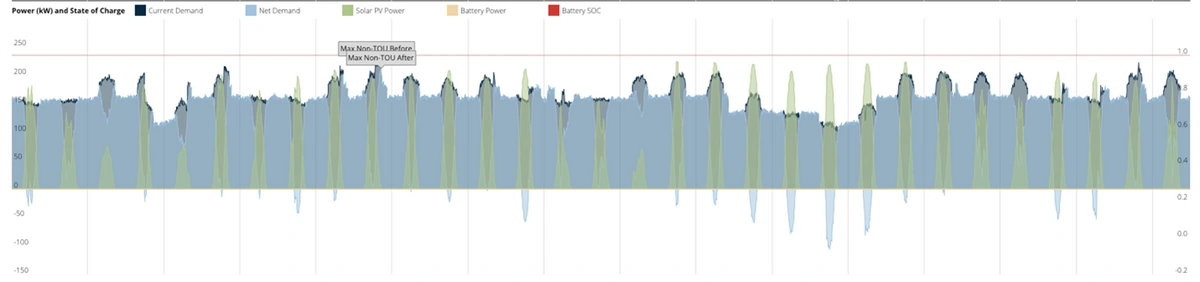

Figure 3: Example of a dynamic EMS peak shaving

In Figure 3, the peak is set, and the EMS no longer cycles the battery on days when the load is not higher than the peak. However, when loads appear higher than the peak, the EMS successfully and efficiently shaves those loads.

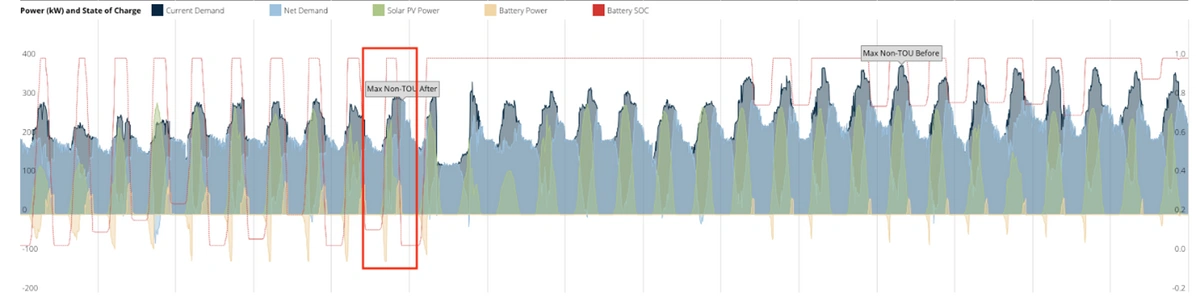

Comparing Fixed vs. Dynamic Savings

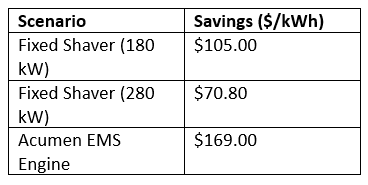

We simulated three scenarios with a single load profile to compare the savings that could be generated across:

- A fixed shaver with a lower threshold (optimal in some months of the year)

- A fixed shaver with a higher threshold (optimal in other months of the year)

- An Acumen EMS (optimizes across all months of the year)

We found the following savings results that demonstrate an increase of 60% in savings beyond the next highest fixed threshold shaver.

Selecting Acumen EMS for Energy Storage

Energy Toolbase maintains over 100 thousand utility rates across thousands of utilities in the United States and across the globe and regularly builds and maintains accurate pricing data for users’ sites. If the pricing data is not already available, the utility rates team creates it and will oversee it moving forward. This data collection and maintenance is incredibly important when Acumen needs pricing data from the database to change its charge and discharge windows accordingly.

Acumen EMS forecasts site loads, learning site patterns to adjust to handle the unpredictable nature of site loads. Acumen adjusts the ideal threshold based on predicted and current load, making real-time decisions to plan. Calculating the total kWh needed to shave a peak is exceptionally complicated, however, Acumen does that 24/7 automatically and executes on that hundreds of times per hour.

Every site has unique variables, from bill date ranges and meter intervals to TOU windows, pricing, site loads, and solar forecasts. Pair all these details with fixed controls or with controls with incorrect rate information, and it will only scratch the surface of the level of performance that Acumen achieves. Energy Toolbase has a team dedicated to optimizing the performance and operation of our fleet available to all our Acumen customers. A last standout feature of Acumen is found in its ability to simultaneously pursue savings across multiple value streams, i.e., value in multiple TOU windows, value across demand, and energy charges.

To explore how Acumen EMS’s dynamic controls can provide additional value for your energy storage projects,sign up for a free trial of the ETB Developer platform. You can also attend ourEnergy Storage Training Webinar that we host weekly to see our entire energy storage modeling module.