Deploying storage can be complex, and many developers face challenges with this relatively new technology. From pricing and sizing the system, to selling, pre-commissioning, commissioning, and end-user education, the Energy Toolbase Operations team helps developers ensure a smooth deployment from the point where the project is sold, all the way into permission to operation (PTO).

The Operations Team handles all energy storage deployments for any developer who purchases an energy storage system paired with ourAcumen EMS™ and works closely with developers to get permitting, designs, installation, and any approvals that a developer needs to ensure a successful deployment. This blog details each step of the process from the experience of the Energy Toolbase Operations Team, covering exactly what each step entails in order to get through a deployment successfully and ensure your customer is satisfied once it is complete.

The Pre-Commissioning Process

Site Assessment

Once you’ve modeled and received the purchase order (PO), developers are tasked with determining what equipment you want to use, which starts with your site assessment. This assessment includes the electrical design, metering and device networking, obtaining the appropriate internet connection requirements, and obtaining the requirements for backup when applicable. The electrical design is comprised of a single-line diagram. You’ll also decide whether you need a transformer, which is critical in pricing the project. Additionally, regarding electrical design, you need to consider if your site might have transient voltages, poor power quality, or unbalanced loads, and may want to consider an isolation transformer if its site voltage is different.

When it comes to metering, it refers to distances from where specific loads need to be metered. As you do your site assessment, think about how many feet of cable you’ll need to wind through the building to get from one place to another, and know those distances. That will impact how metering is done and some of the devices you’ll need. It’s typically inexpensive, but the correct equipment must be ordered and on-site when it goes into the installation phase. Another “gotcha” that developers frequently encounter unexpectedly is the internet connection. Many sites like schools and government facilities have intense firewalls, meaning if you choose to use the local site internet for the energy storage system (ESS), you should consider working with the site’s IT team to get it up and running. Energy Toolbase offers Wi-Fi packages with ruggedized equipment and management assistance but can provide you with a networking document to ensure both parties are aligned with connection instructions if acquired through the site.

The last thing we consider in the site assessment is if the client wants resiliency and backup. This requires extra equipment to disconnect from the grid and other backup panels. With backup, you’ll consider which loads need to get backed up and which do not.

Compliance & Approvals

There are several steps and “to-do’s” in the compliance and approvals phase. Starting that process early is imperative, as utilities typically have exceptionally long lead times and are more comfortable with solar-only projects. Adding an energy storage system usually seems to add time to getting utility and permitting approvals. When handling interconnection agreements, be aware that each selection you make eliminates other choices because it’s menu driven. It’s important to make sure that you carefully read the documents and get advice from your ESS provider if needed.

Permitting can also be challenging, but it is crucial to understand the costs required in terms of service upgrades or utility upgrades. Regarding utility requirements, if transformers need to be replaced on the utility side and they want to charge your client for part of that, that’s something to be aware of.

Understanding Hardware & Software Vendor Scope

The importance of hardware and software selection is sometimes overlooked but plays one of the most significant roles in ensuring the system achieves the expected savings. Energy Toolbase only selects top-tier hardware providers who have a strong reputation in the industry that will honor a warranty – no matter if it is five years or 15 years down the line. Selecting providers with strong track records indicates that they will be there to provide support over the life of the project.

Figure 1: Showing the ESS hardware vendors that Energy Toolbase is partnered with and offers to developers

Isolation transformers are sometimes required for certain projects. It might be something outside of the ESS, but it needs to be included in the electrical design. If you’re doing backup-capable systems, things like SE relays are usually required to disconnect from the grid to start the microgrid islanding process.

Onsite Services & Operations & Maintenance (O&M)

Most onsite services offer ongoing maintenance to systems, which is covered by the vendor and will differ depending on your chosen vendor. Many also require some ongoing maintenance from the installer or provider. Usually, this entails checking the unit over the cleaning filters and other basics. But other times, it’s more boots–on–the–ground to see what’s happening if something looks abnormal from our remote position. Be aware that there are some ongoing costs you should calculate when giving your bid that someone will need to go out to the site occasionally to check on things.

The Commissioning Process

Installation Complete to System Fully Commissioned

You’ve selected your hardware, overcome hurdles, and now the last step is commissioning, which typically takes one to two months. Most battery vendors working with Energy Toolbase provide onsite commissioning of the unit. However, Energy Toolbase does not offer onsite commissioning, as all of it is done remotely. Commissioning generally takes one to three days, depending on the vendor, but can span longer if it’s a microgrid. Generally, it takes Energy Toolbase a little longer to complete the commissioning of the Energy Management System (EMS).

Setting expectations of that timeline with the end-user is important. Each vendor has different requirements, but it usually involves a checklist and photos that show the work is completed. The manufacturer also has commissioning processes they will ask you to go through. Once submitted, that takes around four to six weeks to get the checklist approved and to get the manufacturer to the site.

Commissioning an Energy Management System (EMS)

By now, that process has taken approximately six weeks, and then the EMS provider takes another ten business days to finish our commissioning. Acumen EMS commissioning is quite a manual process, where the Operations team will input rate schedules and conduct testing (site acceptance testing to ensure the battery works as expected). It is also where full capacity discharge tests are done, which takes 24 hours. The process in its entirety can take up to eight weeks and sometimes longer, depending on how smoothly the process goes. The Operations team is very aware of the end goal during the testing and commissioning of the EMS, being to save your customer’s money, so the team takes the time to ensure the EMS will function correctly. Be aware when setting expectations with your customer, and once you’ve completed installation, there is still a bit of time before it goes live and starts saving them money.

Testing & Final Configuration of ESS

At this stage, it’s verified that you have PTO and confirmed that you have the correct rate schedule, and now the system is ready to go live and begin saving money. If some of this information is missing, the system will be put into a “float mode” so that it is just floating and protecting the batteries until the rate schedule is correct or you officially have PTO.

The Division of Responsibilities

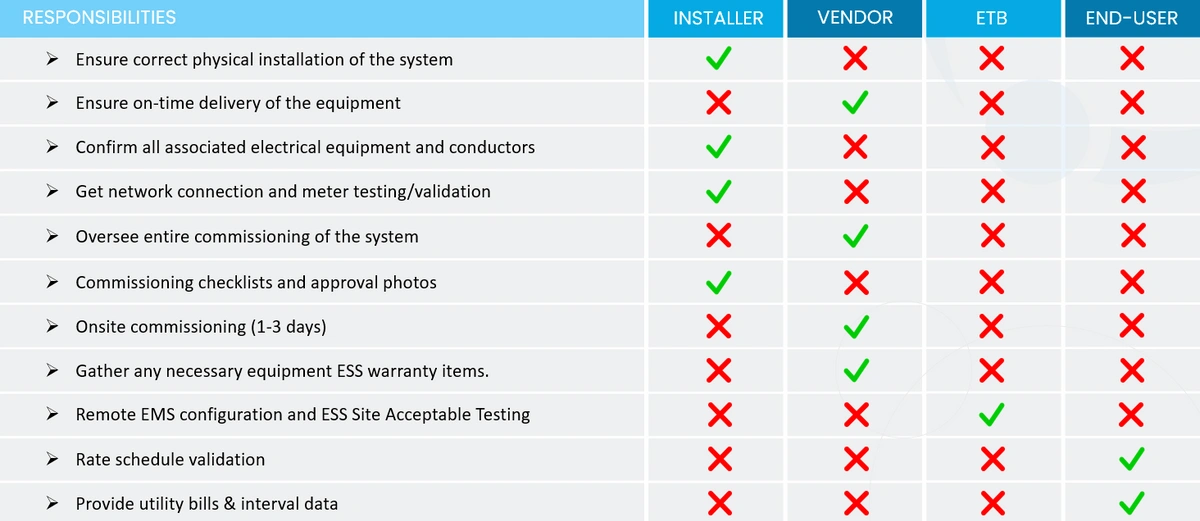

Each party has different responsibilities that all make for a successful deployment. The installer, vendor, EMS provider (Energy Toolbase), and end-user must work together to complete the installation efficiently. We’ve listed below the division of responsibilities:

Energy Toolbase Responsibilities

Energy Toolbase has responsibilities throughout the tenure of these systems as well, primarily through ourETB Monitor platform. ETB Monitor is a robust monitoring software providing real-time insights into the operational performance and savings of solar and energy storage systems and is directly connected to the Acumen EMS. Once the project is completed, installed, and deployed, the Operations team will do in-depth training on the platform and how to utilize it for maximum savings.

The alerting within the ETB Monitor platform will tell end-users or site owners whether the system is down or partially down. For the systems that may have a fault and need onsite support, it is entered into the case tracking system that includes contacts for the end user, if applicable, the O&M provider, or the developer – whoever might be responsible for the system, and the ESS manufacturer. It may require both the electrician and the installer to go to the site to investigate and provide the information requested by the ESS manufacturer to complete their remote analysis of the issue. Energy Toolbase will help coordinate these different parties throughout the life of the system as these faults occur.

End-User Education

Understanding Installation Timelines

The end user is your client, or depending on how it’s financed, this might look like the building owner. You want to ensure the end user is aware of and capable of a couple of things so there are no surprises in the coming years, like understanding the installation (in relation to pre-commissioning) and commissioning timelines, etc. The Operations team can ensure that the developers and the installers understand these timelines so they can set proper expectations for the end user. Manufacturers have very detailed checklists, and they need specific photos to ensure that, remotely, they know everything is completed from when the pictures and checklists are submitted, for when they’re onsite in four to six weeks.

The other expectation is in terms of the battery’s performance and its current economic dispatch. Every site differs depending on the battery’s intention. It could be there for demand charge management, or it could just be there for a demand response program and responding to calls. Or it could be there for time-of-use arbitrage purposes, to predict peaks and understand the load, the solar, and the weather. It takes time for the machine learning algorithms to adapt to specific sites.

Rate Switching

Many of these systems are deployed at sites where the rate schedule that the site is on will change to a different rate once approved, and this enables that system to move to a new rate. The end user is responsible for changing the rate, and they must notify our team of the rate change. Our management system operates based on what we know (i.e., the bills we were provided before installation), and the actions and decisions our system makes could be based on something completely different in rate option A versus rate option B, so to speak. In this way, the energy management system must be updated for changes like a rate switch, so we rely on client information to make those changes.

Low-Level Issue Troubleshooting

The most significant problems are typically related to networking and the internet. Acumen EMS lives on a rugged computer, which is behind different fuse blocks that get fed from the site, and sometimes, transient voltages may trip, blow a fuse, or short the system. In other cases, things may be unplugged, or the network might have changed from one provider to another, and then it must be reconfigured to allow the system to communicate again. Having the proper people on site who understand the local network and where to find these different components is key. We not only want to save installers, electricians, and the battery manufacturer money, but we also want to get the systems on quicker. It’s always the best case for systems to be down for as little time as possible, and the reality is that they do go down. When you’re doing demand charge management and the system is down, and you miss a peak while it’s off, you might miss the savings you would’ve otherwise gained that month. So, setting everyone up for success and letting everyone know that we each play a role in the savings that we intend for the system to make will make everyone happier with the end product and much more satisfied through the process and the life of the system.

As mentioned, this process is complex, and if you miss one step, no matter how big or small, your system’s savings could face some serious consequences. We’ve created an Energy Storage Deployment Checklist to ensure you don’t miss a thing. Feel free todownload the PDF and use it as a valuable resource. You can alwaysset up a call with our team to talk through your energy storage needs.